Response Time of Resistance Thermometers and Thermocouples

The response time of temperature sensors frequently plays an important role in regulating and controlling a range of different processes. But what does response time mean, how is it determined, and what are the normative bases?

The response time is the speed at which a temperature sensor responds to changes in the temperature of the medium to be measured. The response time is usually specified with two different values: T63 and T90

In this case, T stands for the time constant tau (the Greek τ symbol). In physics, the time constant tau is, in simplified form, a time indicator for a dynamic system in which the step response has an exponential course. The unit of measurement is usually in seconds.

The time T63 indicates the time until the temperature sensor has measured 63% of the temperature difference to be measured, while T90 specifies the time for 90% of the temperature difference. Because this is an exponential curve, the time until 63% of the medium temperature is measured plays the most important role. This is because the time increases as the measured temperature approaches the actual medium temperature (see Figure 1). It therefore makes no sense to determine the value, for example, until 100% of the medium temperature is reached. Due to the heat dissipation error, reaching this value is practically impossible. Further information about the influence of the heat dissipation error will be provided in another blog article.

The thermal response time is measured in water at a flow rate > 0.2 m/s and/or in air at a flow velocity of 3 +-0.3 m/s 1.

In practice, the temperature sensor is dipped from a water bath at 25°C into a water bath at 90°C, for example. Both water baths are monitored by a reference sensor. The time until the device under test has reached the water temperature is recorded. This provides the step response of the temperature sensor (blue line in Figure 1). The response time can then be determined from this step response. The time can be determined graphically or calculated from the measured values.

The response time is correctly specified with the two temperatures at which the response time was determined. These temperatures are rarely indicated in the data sheets, however.

In this case, T63 is 1.2 s and T90 is 2.8 s from 25°C → 90°C.

1 Excerpt: DIN EN 60751:2009-05 EN60751:2008

The response time of a temperature sensor depends on the following influencing factors:

Tip: Air is a poor conductor of heat. If you are using an additional protection tube, fill the tip of the protection tube with heat-conducting paste.

The speed at which a temperature sensor must react to a temperature change depends on the requirements for the control circuit. If a rapid response to a change in the controlled variable is required, the response time must be as short as possible. A practical example would be controlling the coolant temperature of an engine or a machine tool. Despite abrupt load changes, the coolant temperature must be kept as constant as possible.

Ultimately, however, a compromise must always be found between the response time and the requirements for the mechanical load capacity of the temperature sensor. In this respect, for example, the flow velocity, temperature, vibration or type of medium play an important role in choosing the correct temperature sensor.

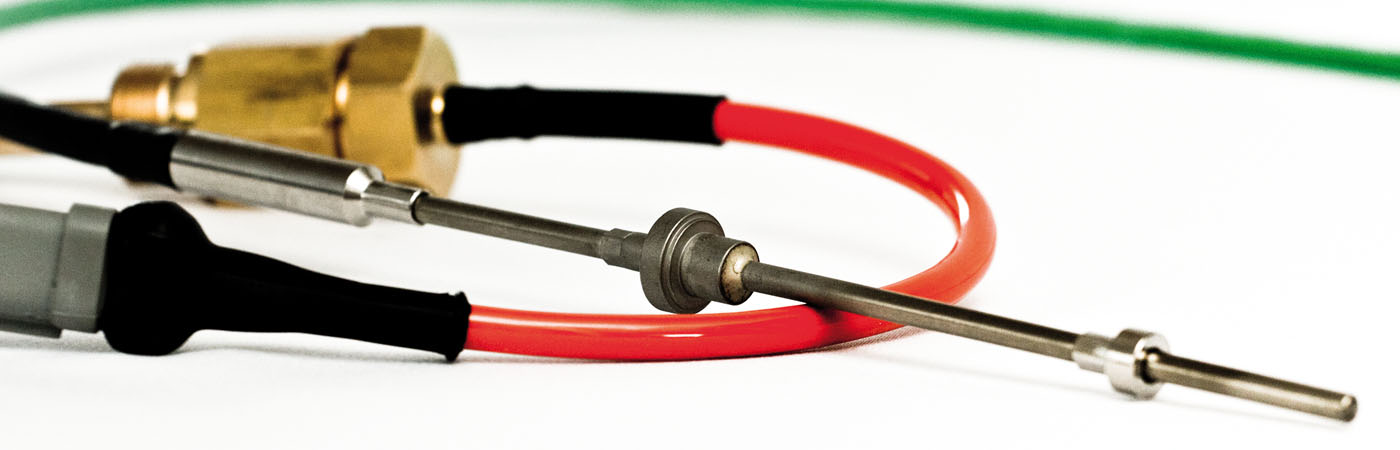

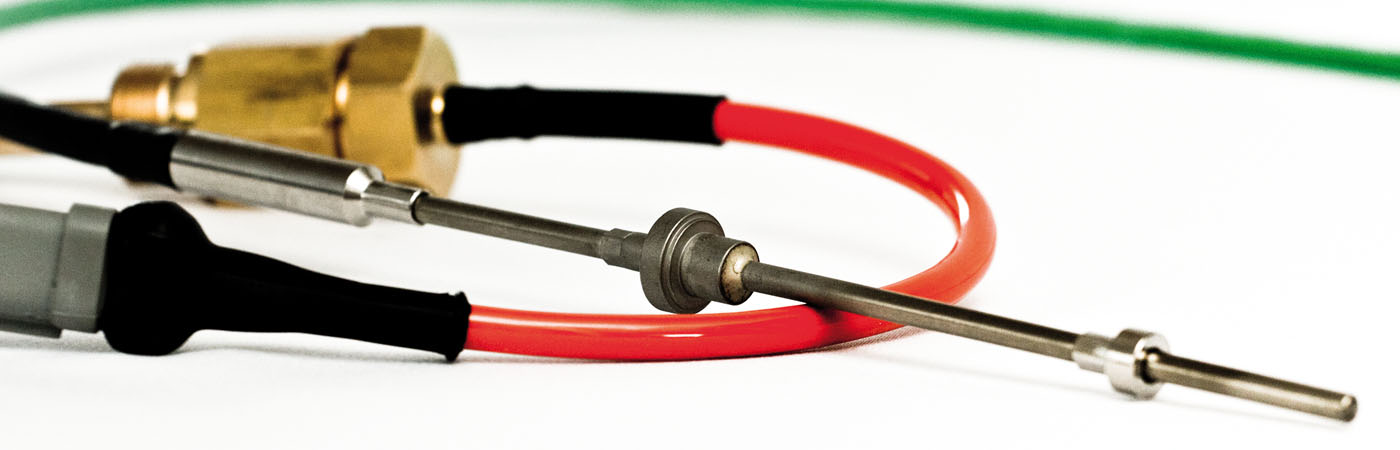

For this purpose, SIKA offers specially designed temperature sensors which are optimised for a rapid response time: temperature sensors in marine configuration, temperature sensors in HVAC configuration and temperature sensors in industrial configuration with IO-Link.