How Does a Turbine Flow Meter Work?

The liquid flowing into the turbine flow meter sets the rotor in motion. The rotor speed is then converted into an electrical pulse signal (frequency). A Hall effect sensor detects the rotation of the rotor, which is fitted with two magnets. The output signal is a flow-proportional frequency signal (square wave signal).

SIKA turbine flow meters are characterized by a long service life: the forces generated during rotation are largely eliminated by the sophisticated design of the rotor. This reduces wear to a minimum. The extremely hard bearing materials sapphire and hard metal also guarantee an exceptional service life.

Turbine flow meters are suitable for volumetric flow detection or the metering of liquids. Owing to their particularly compact design, their very wide measuring range and their impressive measuring accuracy, there are almost unlimited application possibilities.

Benefits of SIKA turbine flow meters:

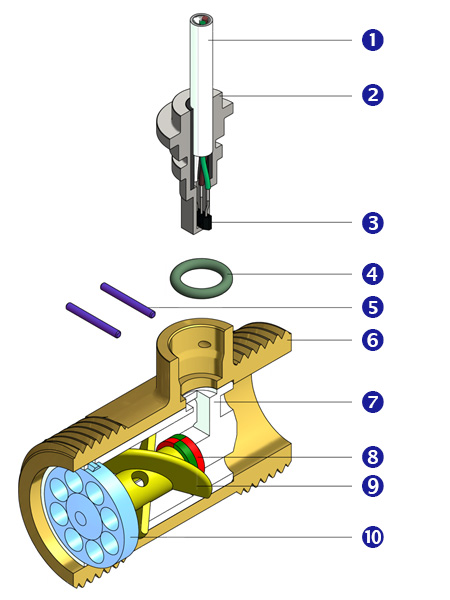

➊ Cable

➋ Sensor housing

➌ Hall effect sensor

➍ O-ring

➎ Fastening pin

➏ Pipe section

➐ Turbine system

➑ Magnet

➒ Rotor

➓ Perforated disc