Calibrate Mechanical Gauges?

There are a lot of reasons why you should calibrate. These include, for example, regulations in various industries such as ISO9000, GMP, FDA, SOLAS, DIN. However, these relate to electronic temperature measuring devices and temperature sensors.

A drift (increasing deviation) of a measuring instrument is caused by:

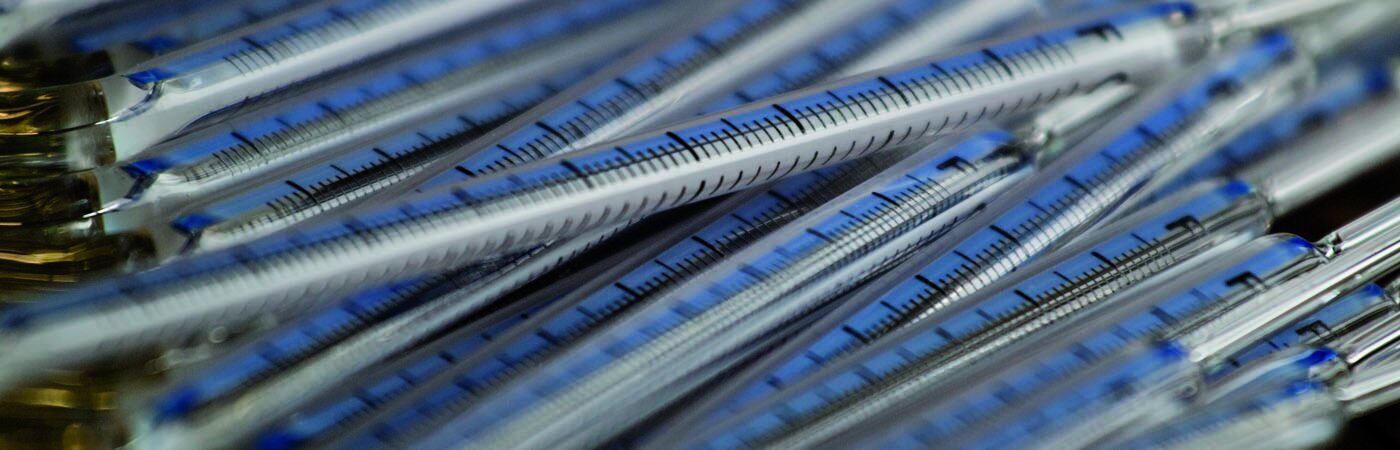

Industrial glass thermometers do not drift. They keep their once-defined accuracy for life. Only the mechanical destruction of the glass insert or a separation of the thermometric filling leads to a failure of the correct measurement. However, both are visible to the naked eye and can be corrected by replacing the glass insert or reuniting the thread.

Nevertheless, there are always attempts to calibrate mechanical measuring instruments. However, for several reasons, this is not an easy thing to do.

According to the calibration instructions for dry block temperature calibrators DKD R5-4 // EA10-/13 // EURAMET CG13, the homogeneous zone, i.e. the range in which the temperature sensor should be calibrated is indicated as 40 mm. This homogeneous zone is usually located at the lower end of the block of the calibrator.

And here begins the difficulty of calibrating mechanical measuring devices: in contrast to temperature sensors, they measure not only at the probe tip, but either predominantly over the entire installation length l1 (industrial glass thermometers) or mainly over a varying active length of the capillary container (dial thermometers). However, the ambient temperature and radiating heat of the housing always act on the parts of the capillary which are not immersed in the medium in thermometers with liquid or gas filling. This is minimised by the design (e.g. bimetallic compensation, ratio of the quantity of medium to be measured and the reservoir/capillary, etc.) and during adjustment to the accuracy required for the device.

If the length of the capillary container is taken into account during the adjustment of the temperature calibrator and the additional measurement uncertainty for a calibration operation is indicated, then dial instruments can of course also be calibrated with a dry block calibrator. However, this requires some background knowledge about the measurement uncertainty that arises with the different installation lengths l1.

Particularly with short installation lengths of industrial glass thermometers (30, 40, 50, 63, 100 mm), the achievement of the homogeneous zone of the calibrator is virtually impossible. In addition, the installation length l1 is measured from the sealing collar. The thread is part of the installation length and therefore requires a special calibration insert with stepped bore.

Industrial glass thermometers and dial thermometers are of course subjected to several tests during production to ensure that the required accuracies are observed (DIN 16195 for industrial thermometers or the different classes for dial thermometers). However, this is not done in calibrators, but in special test systems (baths). These ensure that the measuring instruments are correctly immersed in the medium to be measured and the special features of the measurement with fillings (gas and liquids) are taken into account.